Product Description

| Main Materials | |

| Aluminum | Al6061, Al6063, Al6082, Al7075, Al2571, Al5052, A380, etc. |

| Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416, etc. |

| Steel | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

| Brass | C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc. |

| Copper | C11000, C12000, C12200, C15710, etc. |

| Iron | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. |

| Surface Treatment | |

| Stainless Steel | Brushed and Polishing, Passivating, Sandblasting, Laser engraving, Gold Plating Etc. |

| Steel | Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated |

| Aluminum Parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing,Power Coated, Nickel Plated Etc. |

| Precision Processing | Drilling, Milling, CNC turning, Grinding, Wire cutting, EDM & etc. |

| File formats | STEP, STP, GIS, X-T,CAD,PDF, DWG, DXF etc or Sample |

| Dimension | Customized as drawing or sample |

| Lead Time | Based on the quantity of order (Usually 1Month) |

| Quality System | 100% Inspection before shipment |

| Packing | * Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes * As customer’s specific requirements |

| Shipping | By sea, By air, By DHL,UPS ,TNT& etc. |

Our advantage:

*Specialization in CNC formulations of high precision and high quality

*Independent quality control department

*Control plan and process flow sheet for each batch

*Quality control in all whole production

*Meeting demands even for very small quantities or single units

*Short delivery times

*Excellent price-quality ratio

*Absolute confidentiality *Various materials (stainless steel, iron, brass, aluminum, titanium, special steels, industrial plastics)

RFQ

Q1: How can I get the samples?

A: If you need some samples to test, you should pay for the transportation freight of samples and our samples cost.

Q2: Can we have our marking,Logo or company name to be printed on your products or package?

A: Sure. Your marking,logo,or company name can be put on your products by Laser machine

Q3: How to order?

A: Please send us your purchase order by Email, or you can ask us to send you a Performa invoice for your order. We need to know the following information for your order.

1) Product information-Quantity, Specification ( Size, Material, Technological and Packing requirements etc.)

2) Delivery time required

3) Shipping information-Company name, Street address, Phone&Fax number, Destination sea port.

4) Forwarder’s contact details if there’s any in China.

Q4: When can you get the price?

We usually quote within 48 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority. Kindly note that if your inquiry is with more details then the price we quote will be more accurate

Q5: How can you get a sample to check our quality?

After price confirmation, you can require for samples to check our quality

Q6: What kind of files do we accept for drawing?

A: PDF, CAD,STP,STEP

Q7: What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking,it would need about 30-60days to finish the sample.

Q8: What is our terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the 1 which is the most convenient or cost effective for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 3.5/Piece

1 Piece(Min.Order) | Order Sample According to requirement

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can spiral gears be used in automotive applications?

Yes, spiral gears can be used in automotive applications and provide several advantages in this context. Here’s why spiral gears are suitable for automotive applications:

- Noise Reduction: Spiral gears offer significant noise reduction compared to other gear types, making them ideal for automotive applications that require quiet operation. The helical tooth arrangement minimizes gear meshing noise by providing gradual tooth engagement, reducing impact and vibration.

- Smooth Operation: The gradual tooth engagement of spiral gears also contributes to smoother gear operation. This smoothness helps to improve shifting performance, leading to enhanced driving comfort and reduced wear on transmission components.

- High Load Capacity: Spiral gears have a high load-carrying capacity, which is important in automotive applications where gears are subjected to varying loads. They can handle the torque requirements of transmissions and differential systems effectively.

- Efficient Power Transmission: Spiral gears offer efficient power transmission due to their helical tooth profile. This efficiency helps optimize fuel consumption and overall vehicle performance. By reducing energy losses through improved tooth contact and reduced sliding friction, spiral gears contribute to better power transfer.

- Durability and Reliability: Automotive applications demand gears that can withstand continuous use and provide long-term reliability. Spiral gears are known for their durability, thanks to load distribution and reduced stress concentration. They can maintain reliable performance even under challenging conditions.

- Axial Thrust Compensation: Spiral gears can be designed with opposite helix angles to cancel out axial thrust. This feature is particularly beneficial in automotive applications where minimizing axial forces is crucial. It simplifies gear design and reduces the need for additional components, enhancing space efficiency.

Considering their noise reduction capabilities, smooth operation, high load capacity, efficient power transmission, durability, and axial thrust compensation, spiral gears are well-suited for various automotive applications. They are commonly used in transmissions, differentials, and other drivetrain components to ensure reliable and efficient power transfer, contributing to overall vehicle performance and comfort.

What is the impact of helix angle on spiral gear performance?

The helix angle plays a crucial role in determining the performance characteristics of spiral gears. It affects various aspects of gear operation and functionality. Here’s the impact of the helix angle on spiral gear performance:

- Load-Carrying Capacity: The helix angle influences the load-carrying capacity of spiral gears. A larger helix angle results in a more pronounced helical shape of the teeth, providing a larger contact area between the gears. This increased contact area allows spiral gears to distribute the load over more teeth, thereby increasing their load-carrying capacity. Gears with larger helix angles can handle higher loads and transmit more torque.

- Smoothness of Operation: The helix angle significantly affects the smoothness of gear operation. A larger helix angle leads to a more gradual tooth engagement as the gears mesh. This gradual engagement reduces impact and vibration during gear meshing, resulting in smoother operation and reduced noise levels. Spiral gears with larger helix angles are known for their quiet operation and enhanced gear meshing characteristics.

- Efficiency and Power Transmission: The helix angle also influences the efficiency of power transmission in spiral gears. A larger helix angle reduces sliding friction between the teeth during meshing. This reduction in friction results in improved power transmission efficiency and reduced energy losses. Gears with larger helix angles are more efficient in transmitting power, making them suitable for applications where power efficiency is a critical factor.

- Axial Thrust and Thrust Load: The helix angle affects the axial thrust and thrust load in spiral gears. Axial thrust is the force generated in the axial direction due to the helical tooth arrangement. A larger helix angle produces a higher axial thrust, while a smaller angle generates a lower axial thrust. The axial thrust must be considered and managed in gear design to ensure proper gear support and minimize the need for additional thrust bearings.

- Contact Pattern and Gear Meshing: The helix angle influences the contact pattern between the teeth during gear meshing. A larger helix angle shifts the contact pattern across the tooth face, allowing for more even distribution of the load and reduced stress concentration. The contact pattern also affects the gear meshing characteristics, such as tooth wear and noise generation. Proper selection of the helix angle ensures optimal contact pattern and improved gear meshing performance.

The choice of helix angle in spiral gears depends on the specific application requirements, including load capacity, smoothness of operation, power transmission efficiency, and axial thrust considerations. By selecting an appropriate helix angle, engineers can optimize spiral gear performance for different applications, ensuring reliable and efficient gear operation.

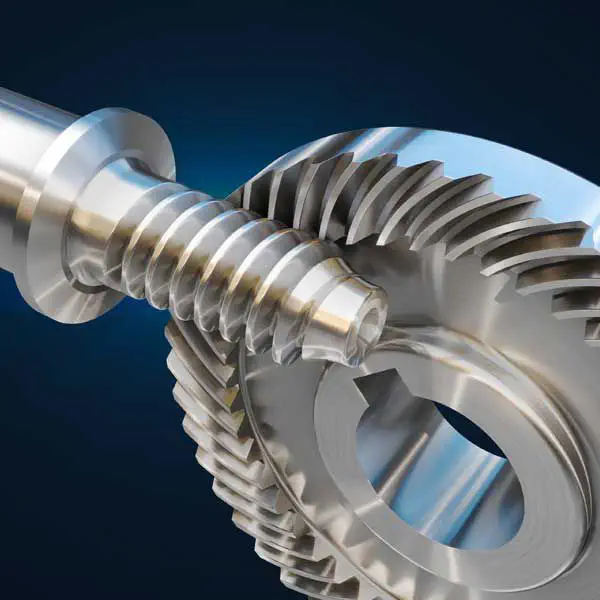

Can you describe the unique tooth profile of spiral gears?

The unique tooth profile of spiral gears, also known as helical gears, sets them apart from other gear types. Here is a description of the key characteristics of the tooth profile:

- Helical Shape: The teeth of spiral gears are helically shaped, meaning they have a curved or slanted form. This helical shape is a result of the helix angle, which is the angle between the tooth surface and the gear axis. The helical shape allows for gradual tooth engagement and smooth gear operation.

- Curved Tooth Surface: The tooth surface of spiral gears is curved or oblique due to the helical shape. This curved profile enables the teeth to engage gradually and smoothly as the gears rotate, reducing impact and noise during gear meshing.

- Lead: The lead of a spiral gear refers to the distance the gear advances axially in one complete revolution. The lead is determined by the helix angle and the number of teeth on the gear. The lead affects the contact pattern and gear meshing characteristics.

- Contact Pattern: When spiral gears mesh, the contact pattern between the teeth changes as the gears rotate. Initially, the contact starts near the smaller end of the tooth and gradually moves across the tooth face as the gears rotate. This shifting contact pattern helps distribute the load over multiple teeth and reduces localized stresses.

- Helix Angle: The helix angle is the angle between the tooth surface and the gear axis. It determines the amount of helical shape in the tooth profile. A larger helix angle results in a more pronounced helical shape, while a smaller angle produces a shallower helix. The helix angle affects the load-carrying capacity, smoothness of operation, and axial thrust characteristics of the spiral gears.

These unique characteristics of the tooth profile in spiral gears, such as the helical shape, curved tooth surface, lead, contact pattern, and helix angle, contribute to their smooth operation, efficient power transmission, and ability to handle high loads. The tooth profile design of spiral gears is crucial in achieving reliable and effective gear meshing in various mechanical systems and applications.

editor by CX 2024-04-12