Product Description

ZheJiang CHINAMFG Parts Manufacturing Co., LTD mainly engages in the parts and assembliesof domestic trucks such as Heavy Duty Truck, ZheJiang Automobile, CHINAMFG Xihu (West Lake) Dis., Xihu (West Lake) Dis.fengXihu (West Lake) Dis.n, Ouman, Beiben, Liugi, etc. The company adheres to theprinciples of honesty and trustworthiness, authenticity, quality and quantity assurance, andreputation first to provide comprehensive services to dealers and suppliers across thecountry. Strictly control quality for customers and provide excellent pre-sales and af-ter-sales service.. mainly engages in the parts and assembliesof domestic trucks such as Heavy Duty Truck, ZheJiang Automobile, CHINAMFG Xihu (West Lake) Dis., Xihu (West Lake) Dis.fengXihu (West Lake) Dis.n, Ouman, Beiben,Liugi, etc. The company adheres to theprinciples of honesty and trustworthiness, authenticity, quality and quantity assurance, andreputation first to provide comprehensive services to dealers and suppliers across thecountry. Strictly control quality for customers and provide excellent pre-sales and af-ter-sales service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Heavy Truck |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Cast Gear |

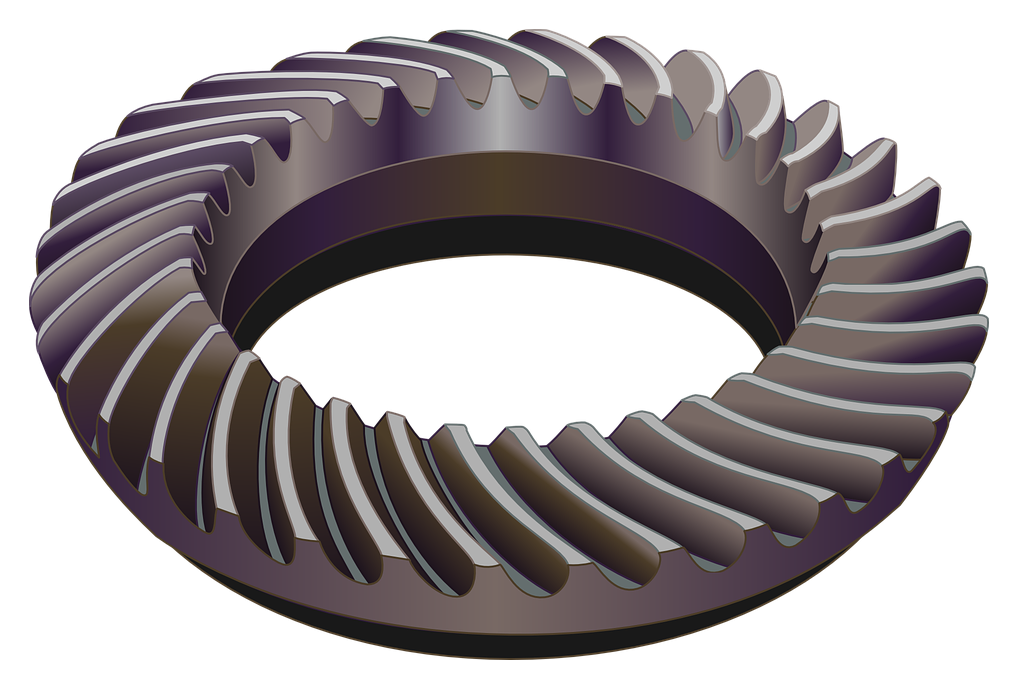

| Toothed Portion Shape: | Bevel Wheel |

| Material: | 20crmnti |

How do spiral gears handle variations in tooth engagement during operation?

Spiral gears are designed to handle variations in tooth engagement during operation effectively. The unique helical tooth arrangement of spiral gears allows them to accommodate these variations and provide several benefits. Here’s how spiral gears handle variations in tooth engagement:

- Gradual Engagement: One of the key advantages of spiral gears is their ability to achieve gradual tooth engagement. As the gears rotate, the helical shape of the teeth allows them to come into contact gradually, starting from one end of the gear to the other. This gradual engagement minimizes the impact and shock that would occur with sudden full tooth contact in other gear types. It results in smoother and quieter operation, reducing noise, vibrations, and stress on the gear system.

- Increased Tooth Contact Area: Spiral gears provide a larger tooth contact area compared to straight-cut or spur gears. The helical tooth profile extends the contact length along the gear face, distributing the load over multiple teeth at any given moment. This increased contact area enables spiral gears to handle higher loads and transmit torque more efficiently.

- Load Sharing: Due to the helical arrangement, spiral gears naturally distribute the load across multiple teeth. This load-sharing characteristic helps to minimize tooth wear and fatigue. As the gears rotate, different teeth come into contact, ensuring that the load is distributed evenly. This load sharing capability enhances the gear system’s durability and extends its service life, particularly in applications with fluctuating loads.

- Reduction of Side Thrust: Spiral gears generate an axial thrust force during operation. However, by using pairs of spiral gears with opposite helix angles, this side thrust force can be greatly reduced or even eliminated. When paired gears with opposite helix angles mesh together, the axial thrust forces cancel each other out. This eliminates the need for additional thrust bearings or complex gear arrangements to counteract the axial forces, simplifying the gear system design.

- Improved Lubrication: The helical tooth profile of spiral gears promotes better lubrication. The continuous sliding motion between the teeth creates a pumping action that helps distribute lubricant along the tooth surfaces. This improved lubrication reduces friction, heat generation, and wear, enhancing the overall efficiency and longevity of the gear system.

These features of spiral gears—gradual engagement, increased tooth contact area, load sharing, reduction of side thrust, and improved lubrication—make them highly effective in handling variations in tooth engagement during operation. Spiral gears are commonly used in various applications such as automotive transmissions, industrial machinery, and power generation systems, where smooth and reliable power transmission is crucial.

What are the benefits of using spiral gears in high-torque applications?

Spiral gears, also known as helical gears, offer several benefits when used in high-torque applications. These advantages make them well-suited for transmitting large amounts of torque efficiently and reliably. Here are the key benefits of using spiral gears in high-torque applications:

- High Load Capacity: Spiral gears are designed to handle high loads and transmit significant amounts of torque. The helical tooth arrangement allows for load distribution across multiple teeth, reducing stress concentration on individual teeth. This design feature enables spiral gears to withstand the heavy forces encountered in high-torque applications.

- Smooth and Efficient Power Transmission: The helical shape of the teeth in spiral gears enables smooth and continuous contact between the mating gears. This gradual tooth engagement results in reduced impact and vibration during gear meshing. Additionally, the helical tooth profile minimizes sliding friction, leading to efficient power transmission and reduced energy losses, which is particularly important in high-torque applications where power efficiency is crucial.

- Reduced Noise and Vibration: The gradual tooth engagement and improved contact pattern in spiral gears contribute to reduced noise and vibration during operation. The helical tooth arrangement helps to distribute the load more evenly, minimizing dynamic forces and resulting in quieter gear operation. This is especially beneficial in high-torque applications where noise reduction is desired, such as precision machinery or noise-sensitive environments.

- Axial Thrust Compensation: Spiral gears can be designed with opposite helix angles on mating gears, which helps cancel out the axial thrust generated during gear meshing. This feature is particularly advantageous in high-torque applications where managing axial forces is critical. By eliminating or reducing the axial thrust, spiral gears simplify the gear design and reduce the need for additional components, such as thrust bearings.

- Reliability and Durability: The robust design of spiral gears, combined with their ability to handle high loads and transmit torque efficiently, contributes to their overall reliability and durability in high-torque applications. The gradual tooth engagement, load distribution, and reduced friction help minimize wear and extend the service life of the gears, ensuring long-term performance under demanding conditions.

These benefits make spiral gears an excellent choice for high-torque applications where reliable and efficient power transmission, smooth operation, reduced noise, and durability are essential requirements.

How do spiral gears differ from other types of gears?

Spiral gears, also known as helical gears, have distinct differences compared to other types of gears. These differences primarily stem from the helical tooth arrangement in spiral gears. Here’s how spiral gears differ from other gear types:

- Helical Tooth Arrangement: Spiral gears have teeth that are curved in a spiral pattern, forming a helix. This is different from straight-cut gears, which have teeth parallel to the gear axis, or bevel gears, which have teeth on conical surfaces. The helical tooth arrangement in spiral gears provides various advantages such as smoother operation, increased load capacity, and improved efficiency.

- Gradual Tooth Engagement: Due to the helical tooth arrangement, spiral gears have a gradual tooth engagement as the gears rotate. This gradual contact reduces impact and noise during gear meshing, resulting in smoother and quieter operation compared to straight-cut gears.

- Axial Thrust Compensation: Spiral gears can be designed with opposite helix angles on mating gears, which helps in canceling out the axial thrust generated during gear meshing. This feature eliminates the need for additional thrust bearings and simplifies the gear design, reducing complexity.

- Load Distribution: The helical tooth arrangement in spiral gears allows the load to be distributed over multiple teeth. This enables spiral gears to handle higher torque transmission and carry heavier loads compared to straight-cut gears.

- Efficiency: Spiral gears exhibit higher efficiency due to reduced sliding friction between the teeth. The helical tooth arrangement helps minimize sliding friction, resulting in lower power losses during gear operation.

- Versatility: Spiral gears can be manufactured in various configurations, including spur, helical, and double helical designs. This versatility allows for their application in a wide range of machinery and systems, providing flexibility in gear design and usage.

These differences make spiral gears well-suited for applications that require smooth operation, high load capacity, and efficient power transmission. They are commonly used in gearboxes, automotive differentials, machine tools, and various industrial machinery.

In summary, spiral gears stand out from other gear types due to their helical tooth arrangement, resulting in smoother operation, increased load capacity, improved efficiency, and versatility.

editor by CX 2024-04-11